10MM rau 130MM Casting Sib Tsoo Media Steel Pob rau Pob Zeb Hlau Mines thiab Cement Cog

Khoom piav qhia

Cov txheej txheem ntau lawm

Lub pob casting, tseem hu ua lub pob zeb sib tsoo, yog tsim los ntawm cov khoom seem hlau, cov hlau nplaum, thiab lwm yam khoom pov tseg. Cov ntaub ntawv hais saum toj no yog molten heev thiab ua ib qho txuas ntxiv tom qab tau rhuab. Thaum lub sij hawm smelting theem, ib tug loj npaum li cas ntawm hlau ntsiab xws li vanadium, hlau thiab manganese yog thawj zaug ntxiv rau lub flue roj kom ua tau raws li qhov xav tau thiab predetermined tawm los. Cov ntsiab lus no tuaj yeem nchuav cov hlau super-molten rau hauv cov kab ntau lawm ntawm cov nroj tsuag steelmaking.

Daim ntawv thov

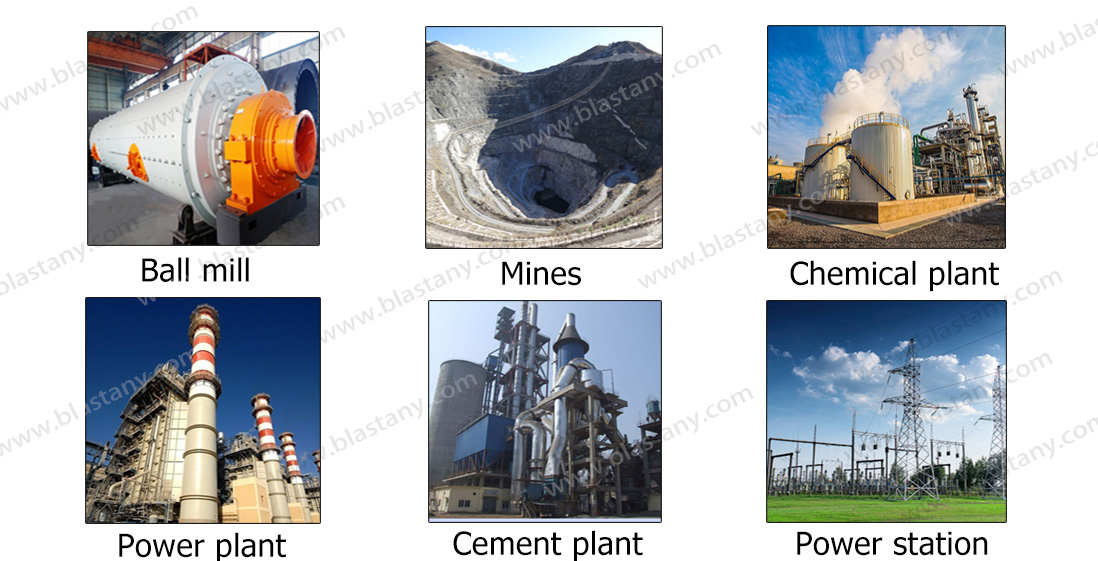

Casting Steel Ball tuaj yeem siv dav hauv ntau daim ntawv thov, suav nrog

Silica xuab zeb Hoobkas / Cement cog / Tshuaj cog / Fais fab nroj tsuag / Mines / Fais fab chaw nres tsheb

/ Tshuaj industries / Sib tsoo zeb / Pob zeb / Coal zeb

Taw qhia txog cov khoom lag luam steel pob

Chrome cam khwb cia steel npas yog cov cam khwb cia sib tsoo xov xwm khoom uas muaj ib feem ntawm chromium, thiab los ntawm cov uas tau muab faib ua high chromium cam khwb cia steel npas, nruab nrab chromium cam khwb cia steel npas thiab tsawg chromium cam khwb cia steel pob. Cov chromium cam khwb cia steel pob tau muab faib ua High Chromium Cast Steel Balls, Nruab Nrab Chromium Cast Steel Balls thiab Low Chromium Cast Steel Balls. Nrog cov yam ntxwv ntawm siab hardness, tsis tshua muaj hnav, thiab tsis tshua muaj tawg, cam khwb cia hlau sib tsoo pob yog tsuas yog siv hauv kev lag luam cement, kev lag luam mining, metallurgical kev lag luam, kev lag luam tsim hluav taws xob thiab kev tsim kho kev lag luam.

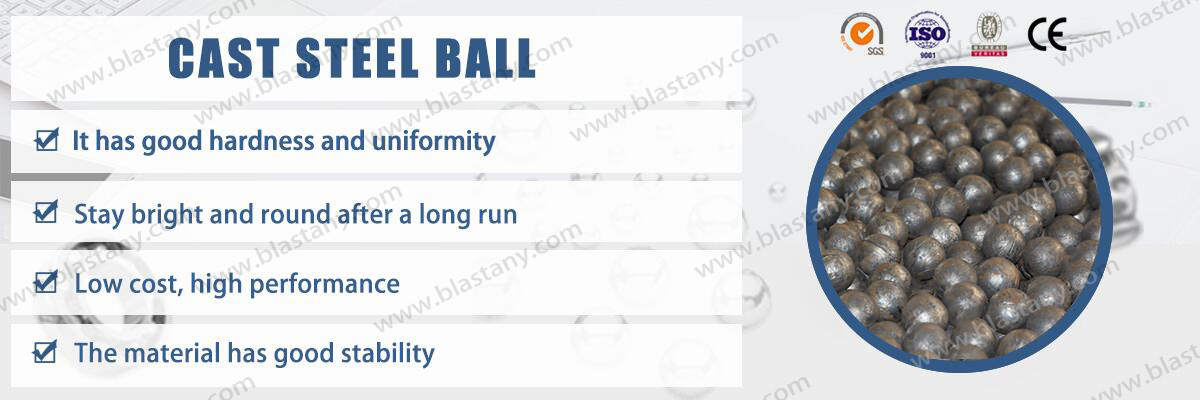

Cast Grinding Steel Ball Nta

1 、 Cov khoom siv raw yog tag nrho cov kabmob steel scraps, uas muaj tooj liab, molybdenum, npib tsib xee thiab lwm yam hlau tseem ceeb, uas tuaj yeem txhim kho cov qauv matrix ntawm lub pob steel.

2 、 Peb cov khoom yog tsim los ntawm nruab nrab zaus hluav taws xob rauv uas tuaj yeem ua kom muaj kev ruaj ntseg ntawm cov khoom. Cov pob tsis yooj yim rau tev tawm thiab deform thaum siv. Txawm tias nws tuaj yeem ua kom ci thiab puag ncig tom qab ua haujlwm ntev.

3 、 Cov khoom siv hluav taws xob loj tshaj plaws tsis siv neeg quenching cov kab ntau lawm yog siv rau kev kho cua sov, uas ua kom cov hardness zoo thiab uniformity ntawm cov khoom.

Peb txoj kev ua cov pob steel

1. Peb txoj kev tsim khoom steel pob

Muaj peb hom steel pob raug txheej txheem: casting, forging, thiab dov.

(1) Casting: Qhov zoo ntawm cam khwb cia hlau pob tsuas yog nyob ntawm cov ntsiab lus chromium. Nyob rau hauv xyoo tas los no, tus nqi nce ntawm chromium, kev tiv thaiv ib puag ncig, thiab lwm yam tau ua rau muaj kev nce nqi ntawm cov cam khwb cia hlau.

(2) Forging: Siv high manganese steel li raw khoom, pneumatic forging rauj thiab pob pwm yog siv los ua cov pob steel. Forged steel npas muaj qhov tsim nyog ua ke ntawm high-carbon, manganese, chromium, thiab lwm yam hlau alloy, thiab muaj zog hardenability hauv kev kho cua sov, me me sib txawv hardness ntawm sab hauv thiab sab nraud, thiab qhov sib txawv ntawm cov nqi, uas ua rau cov khoom forged muaj zog dua cov pob cam khwb cia.

(3) Rolling: Siv high manganese steel tuav ua raw cov ntaub ntawv, steel pob yog tsim los ntawm ib tug skew dov zeb nrog kauv chais.

| Yam khoom | Chemical Composition (%) | |||||||||

| C | Si | Mn | Cr | P | S | Mo | Cu | Ni | ||

| Siab chrome cam grinding pob | ZQCr12 | 2.0-3.0 Nws | 0.3-1.2 hli | 0.2-1.0 | 11-13 | ≤ 0.10 | ≤ 0.10 | 0-1.0 | 0-1.0 | 0-1.5 hli |

| ZQCr15 | 2.0-3.0 Nws | 0.3-1.2 hli | 0.2-1.0 | 14-17 | ≤ 0.10 | ≤ 0.10 | 0-1.0 | 0-1.0 | 0-1.5 hli | |

| ZQCr20 | 2.0-2.8 Nws | 0.3-1.0 | 0.2-1.0 | 18-22 | ≤ 0.10 | ≤ 0.08 | 0-2.0 Nws | 0-1.0 | 0-1.5 hli | |

| ZQCr26 | 2.0-2.8 Nws | 0.3-1.0 | 0.2-1.0 | 22-28 | ≤ 0.10 | ≤ 0.08 | 0-2.5 hli | 0-2.0 Nws | 0-1.5 hli | |

| Middle chrome cam khwb cia sib tsoo bal ls | ZQCr7 | 2.0-3.2 | 0.3-1.5 hli | 0.2-1.0 | 6.0-10 | ≤ 0.10 | ≤ 0.08 | 0-1.0 | 0-0.8 hli | 0-1.5 hli |

| Tsawg chrome cam khwb cia sib tsoo pob | ZQCr2 | 2.0-3.6 | 0.3-1.5 hli | 0.2-1.0 | 1.0-3.0 Nws | ≤ 0.10 | ≤ 0.08 | 0-1.0 | 0-0.8 hli | |

High chromium casting parameters (High Chrome Ball Parameter)

| Nominal txoj kab uas hla | Qhov hnyav ntawm ib pob hauv qhov nruab nrab (g) | Ntim / MT | Surfacehardness(HRC) | Endurance Impact Test (Lub Sijhawm) |

| φ15 | 13.8 ib | 72549 ib | > 60 | > 10000 |

| φ17 | 20.1 | 49838 ib | > 10000 | |

| φ20 | 32.7 ib | 30607 ua | > 10000 | |

| φ25 | 64 | 15671 ib | > 10000 | |

| φ30 | 110 | ib 9069 | > 10000 | |

| φ40 | 261 | ib 3826 | > 10000 | |

| φ 50 | 510 | Xyoo 1959 | > 10000 | |

| φ60 | 882 ib | 1134 ib | > 10000 | |

| ib 70 | 1401 | 714 ib | > 10000 | |

| ib φ80 | 2091 ib | 478 ib | > 58 | > 10000 |

| f90 ua | 2977 ib | 336 | > 10000 | |

| φ100 | ib 4084 | 245 | > 8000 | |

| φ120 | ib 7057 | 142 | > 8000 | |

| φ130 | ib 8740 | 115 | > 8000 |

Cov khoom qeb