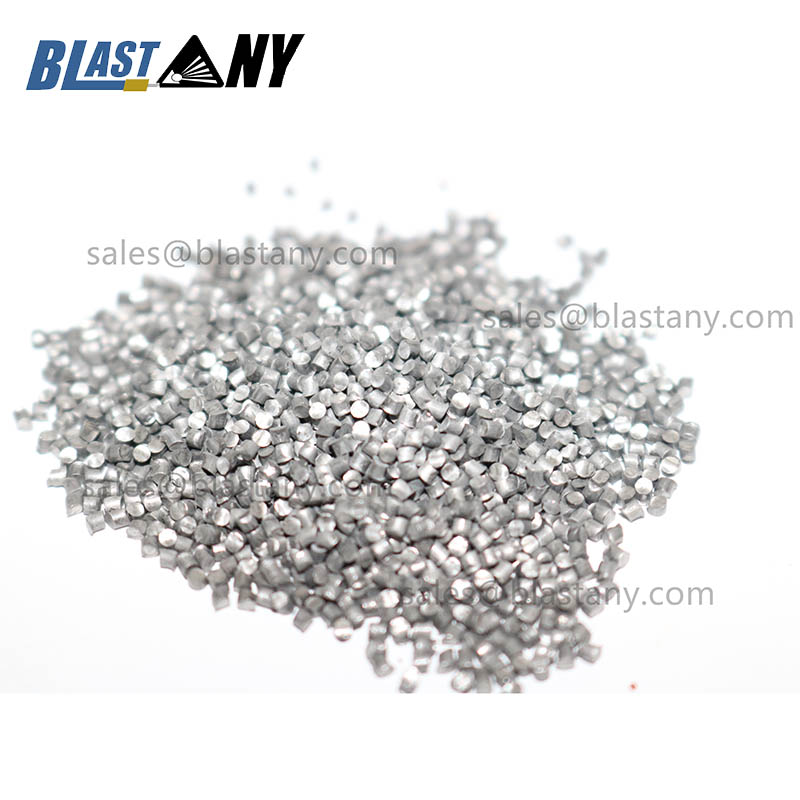

Siab muaj zog qaug zog tiv taus hlau tua

Hom Hlau Hlau Txiav Txhaj Tshuaj

0.8mm 1.0mm 1.5mm 2.0mm 2.5mm

Tau txais kev siv xaim txiav tshuaj

1. Hlau hlau phom tua ntxiv: Txhaj tshuaj tiv thaiv kev txhaj tshuaj ntxiv, txhaj koob tshuaj tiv thaiv kev txhaj tshuaj ntxiv ntawm cov cua sov kho kom zoo.

2

3. Hlau hlau Txhaj Tshuaj Kho: Tuag Casting Tu, Hlau Tu, Hlau Tu, Hlau Steel Tu, Hlau Qauv Tu.

4. Cov hlau xaim xaim txiav Derusting derusting: txhaj koob tshuaj tivthaiv Derusting, Forgings Derusting, Hlau Derusting, H-Nqaum Derusting Steel qauv derusting.

5. Cov hlau xaim txiav tua cov xuab zeb: xuab tshem tawm.

6. Hlau hlau tua cov hlau ua txuj ci: txheej pretreatment, ntu portreatment, ntu steel pretreatment, steel pretreatment, steel pretreatment, steel qauv pretricement.

7. Hlau hlau tua Blasting: Hlau phaj tua Blasting, Steel Blasting Blasting, Steel Txhaj Blasting.

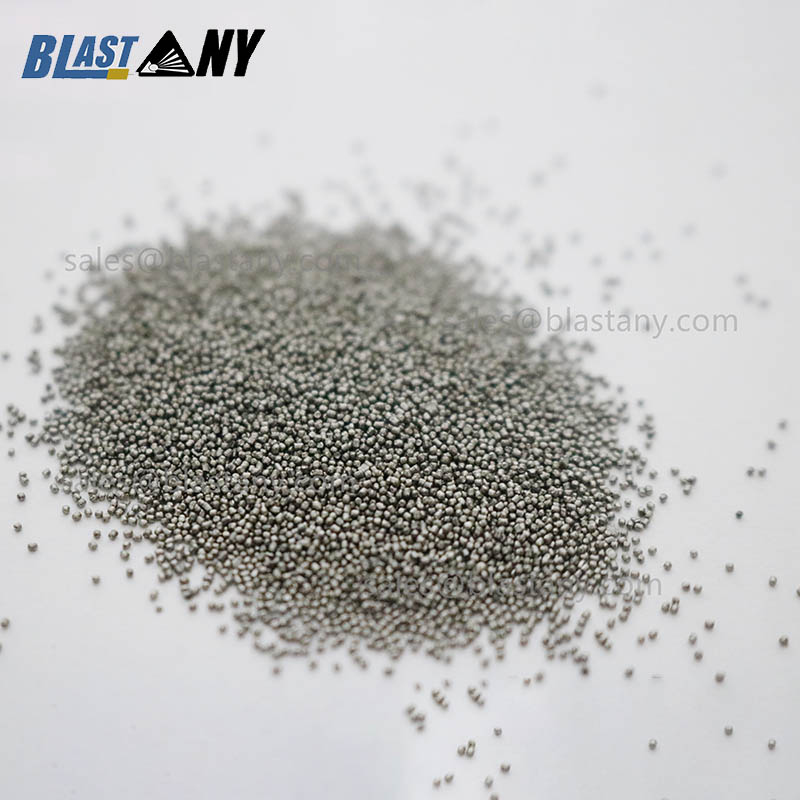

Siv tau cov khoom siv rau cov hlau hlau tua

Hlau hlau tua tej yog siv rau cov kab ntau ntau heev, cov khoom siv tawg, cov khoom tawg ua ntej tshuab, xuab zeb blasting khoom abrasive.

Kev tsis muaj

| Khoom | Txiav Hlau Tshuab | |

| C | 0.45 ~ 0.75% | |

| Mn | 0.40 ~ 1.20% | |

| Tshuaj Muaj Tshuaj | Si | 0.10 ~ 0.30% |

| S | 0.04% | |

| P | 0.04% | |

| Microhardness | 1.0 hli 51 ~ 53 hrc (525 ~ 561hv) | |

| Kev siv hluav taws xob tensile | 1.0mm 1750 ~ 2150 MPA | |

| Ceev | 7.8g / cm3 | |

Cov khoom lag luam