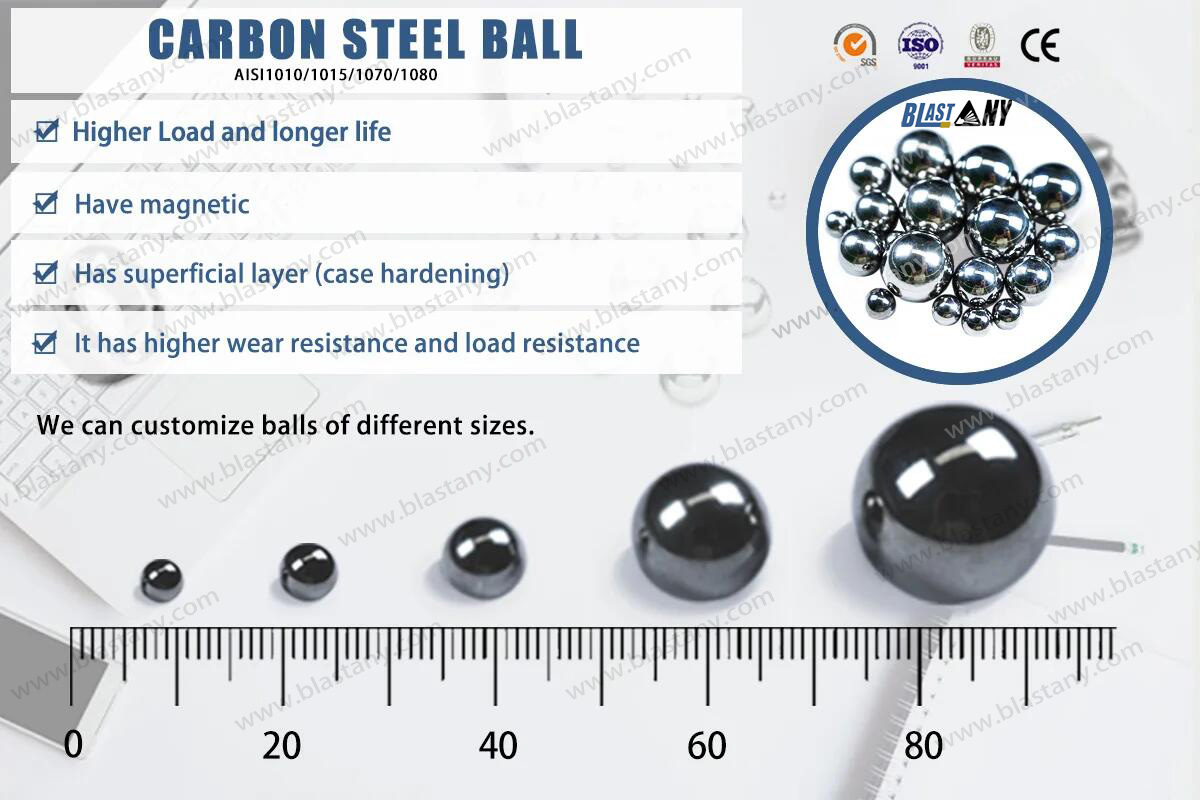

AISI1010/1015/1085 High / Low carbon steel pob 0.8 hli - 50.8 hli Carbon steel pob rau tsheb kauj vab bearings saw log

Khoom piav qhia

Tsawg Carbon Steel Pob.

| Khoom siv | AISI 1010/1015 |

| Qhov Loj | 0.8mm-50.8 hli |

| Qib | G100-G1000 |

| Hardness | HRC: 55-65 |

Product Description

Nta:

muaj hlau nplaum, Carbon Steel Balls muaj txheej txheej sab nraud (cov ntaub ntawv tawv), thaum lub pob sab hauv ntawm lub pob tseem mos metallographic tructure yog ferrite, pob feem ntau nrog roj. Feem ntau electroplating thaum nws tawm ntawm qhov chaw, nws tuaj yeem plated nrog zinc, kub, npib tsib xee, chrome thiab lwm yam. muaj zog tiv thaiv hnav ua haujlwm .Kev sib piv: hnav-tiv taus thiab hardness tsis zoo dua li cov kabmob steel pob (HRC ntawm GCr15 steel pob yog 60- 66): yog li, lub neej luv dua.

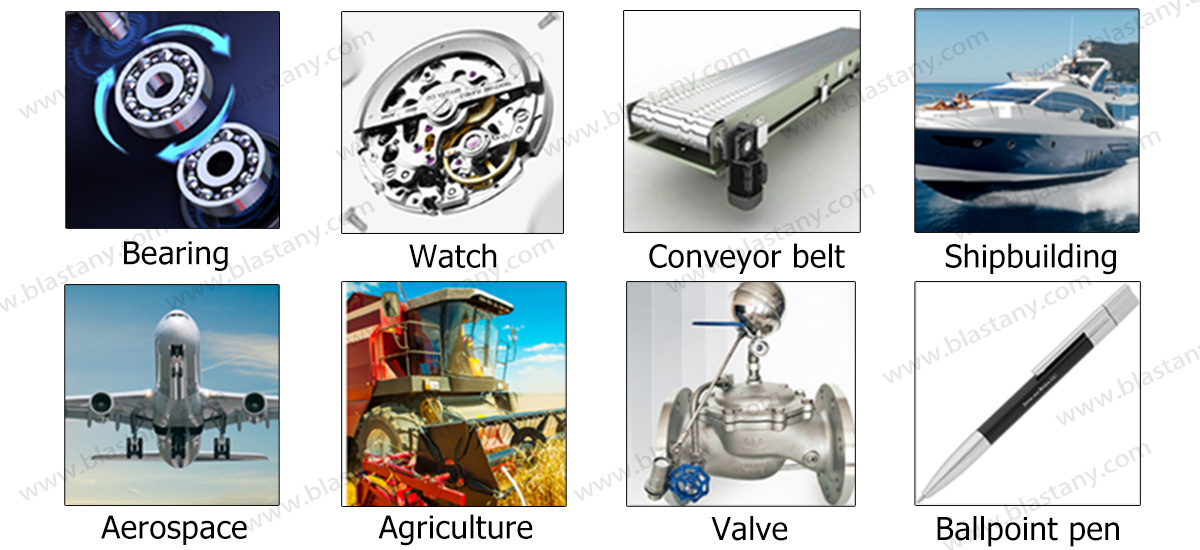

Daim ntawv thov:

1010/1015 carbon steel pob yog lub pob hlau zoo tib yam, nws muaj tus nqi qis, siab precision thiab dav siv. Nws yog siv rau hauv tsheb kauj vab, bearings, saw log, craftwork, txee, ntau yam pob, hnab, khoom me me, kuj tseem siv tau los txhuam lwm yam nruab nrab.Castors, Dressers 'Bearings, Locks, Oilers Thiab Grease Cups, Skates.drawers Slides Thiab Qhov rai Rolling Bearings, Cov Khoom Ua Si, Siv thiab Cov Menyuam Menyuam.

| Hom khoom | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1010 (C10) | 0.08-0.13 dr hab | 0.10-0.35 dr hab | 0.30-0.60 Nws | 0.04 ib | 0.05 Nws |

| AISI 1015 (C15) | 0.12-0.18 dr hab | 0.10-0.35 dr hab | 0.30-0.60 Nws | 0.04 ib | 0.05 Nws |

High Carbon Steel Pob

| Khoom siv | TIAB SA 1085 |

| Qhov Loj | 2mm-25.4 hli |

| Qib | G100-G1000 |

| Hardness | HRC 50-60 |

Product Description

Nta:

AISI1070/1080 Carbon Steel Balls, & High carbon steel npas muaj qhov zoo tshaj plaws nyob rau hauv cov nqe lus ntawm tag nrho cov hardness Performance index, uas yog hais txog 60/62 HRC thiab muab ib tug ntau dua hnav thiab load kuj piv rau cov uas tsis muaj carbon hardened steel pob.

(1) Core-hardened

(2) Tsawg tsis kam rau corrosive nres

(3) Ntau dua Load thiab lub neej ntev dua li cov pa roj carbon tsawg

Daim ntawv thov:

Tsheb kauj vab accessories, rooj tog pob bearings, zawv zawg cov lus qhia, conveyor siv, hnyav load log, pob txhawb nqa units. Tsawg precision bearings, tsheb kauj vab & automotive Cheebtsam, agitators, skates, polishing thiab milling tshuab, Tsawg precision bearings.

| Hom khoom | C | Si | Mn | P (MAX.) | S (MAX.) |

| AISI 1070 (C70) | 0.65-0.70 Nws | 0.10-0.30 Nws | 0.60-0.90 Nws | 0.04 ib | 0.05 Nws |

| AISI 1085 (C85) | 0.80-0.94 Nws | 0.10-0.30 Nws | 0.70-1.00 Nws | 0.04 ib | 0.05 Nws |

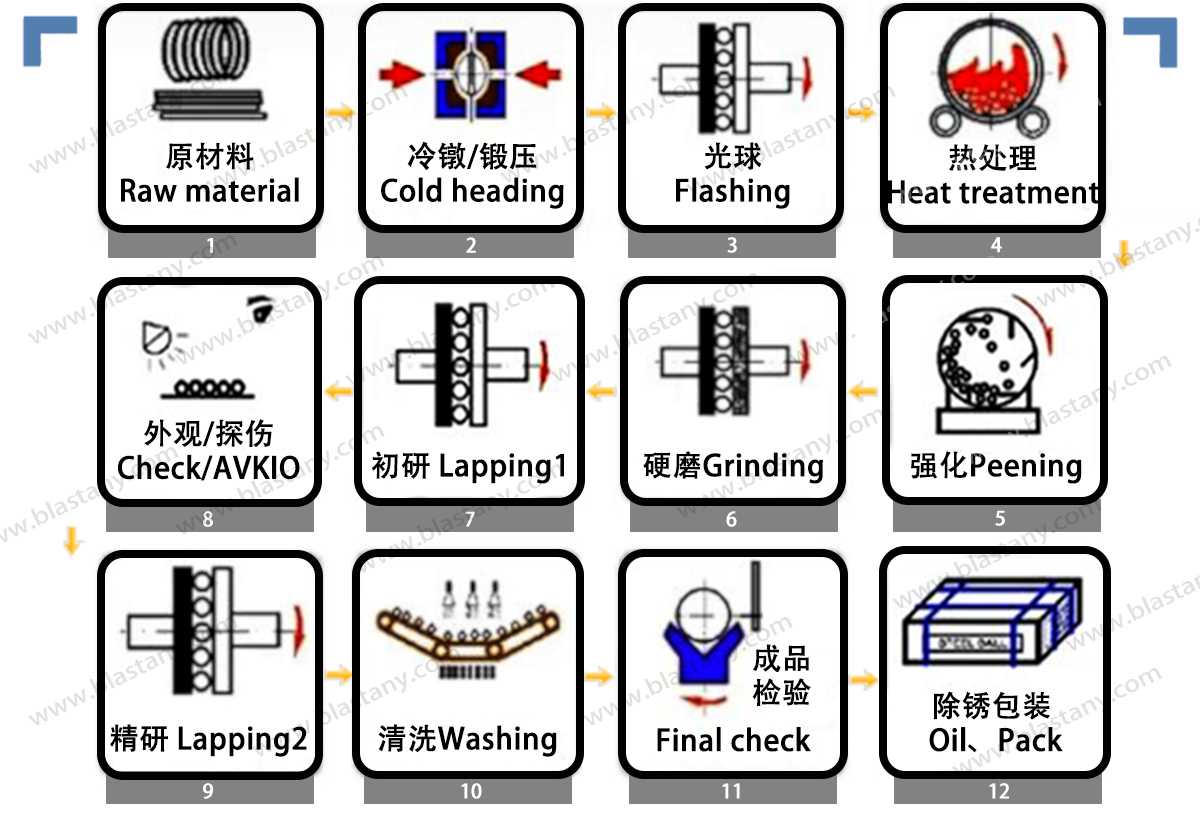

Cov txheej txheem ntau lawm

Cov txheej txheem tsim khoom ntawm Precision Pob Khoom

1.Law Material

Thaum nws pib theem, ib lub pob pib nyob rau hauv daim ntawv hlau los yog pas nrig. Kev tswj kom zoo mus los ntawm kev sim metallurgic kom ntseeg tau tias cov khoom muaj pes tsawg leeg nyob rau hauv qhov kev siv tau.

2. Lub taub hau

Tom qab cov khoom siv raw tau dhau kev tshuaj xyuas, nws yog tom qab noj los ntawm kev kub ceev header. Qhov no ua cov pob ntxhib heev.

3.Flashing

Cov txheej txheem flashing ntxuav cov pob taub hau kom lawv zoo me ntsis hauv qhov tsos.

4. Kev kho cua sov

Cov txheej txheem kub heev uas cov pob flashed tau muab tso rau hauv qhov cub muaj. Qhov no hardens lub pob.

5. Sib tsoo

Lub pob yog hauv av mus rau kwv yees txoj kab uas hla ntawm lub pob zaum kawg.

6. Lapping

Lub lapping ntawm lub pob coj nws mus rau nws qhov xav tau kawg qhov ntev. Qhov no yog qhov kawg kev tsim thiab tau txais lub pob nyob rau hauv qib tolerances.

7. Kev soj ntsuam zaum kawg

Lub pob yog tom qab ntawd ntsuas qhov tseeb thiab tshuaj xyuas los ntawm Kev Tswj Xyuas Zoo kom ntseeg tau tias qhov zoo tshaj plaws.

Cov khoom qeb