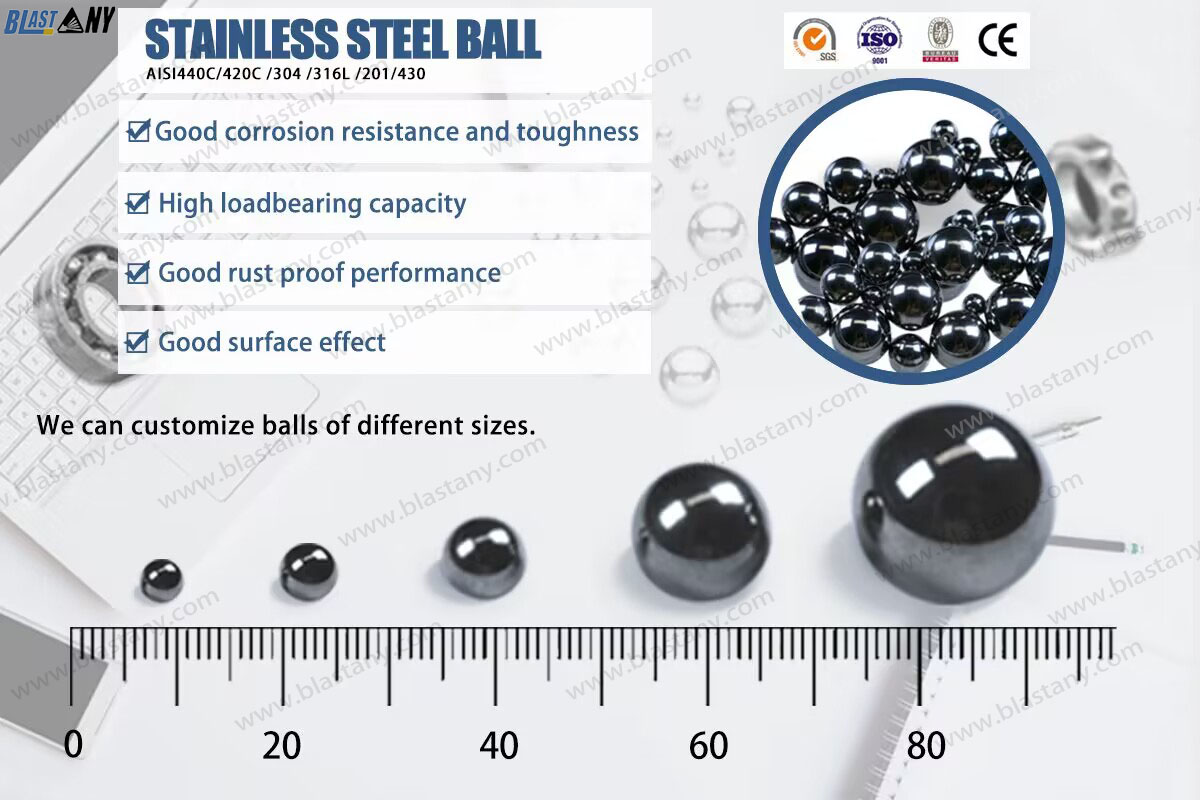

Hoobkas mov 0.35mm-50.8mm HRC50-55 lub teeb AISI304 316 430 440 stainless hlau pob Siv nyob rau hauv Bearing

Khoom piav qhia

Cov pob stainless hlau muaj peev xwm tiv thaiv corrosion los ntawm cov neeg ua haujlwm xws li oxidizing kev daws teeb meem, feem ntau cov organic chemicals, khoom noj khoom haus thiab cov tshuaj sterilizing. Lawv muaj nruab nrab resistant rau sulfuric acids. Cov khoom tsis sib nqus muaj nyob rau ntawm kev thov. Cov ntawv thov muaj xws li aerosol, sprayers, ntiv tes twj tso kua mis mechanisms, mis nyuj tshuab blenders, khoom noj khoom haus thiab kev siv kho mob.

AISI 440C Stainless hlau pob

Loj: 0.35mm-50.8mm

Qib: G10, G16, G40, G60, G100, G200.

Hardness: HRC56-58, Hartford 440C stainless hlau pob yog passivated kom tshem tawm cov hlau tsis muaj paug thiab pab txhawb kev tsim cov yeeb yaj kiab tiv thaiv.

Sib nqus: Martensitic hlau, sib nqus

Nta: siab precision, zoo corrosion kuj, muaj zog xeb thiab hnav tsis kam.

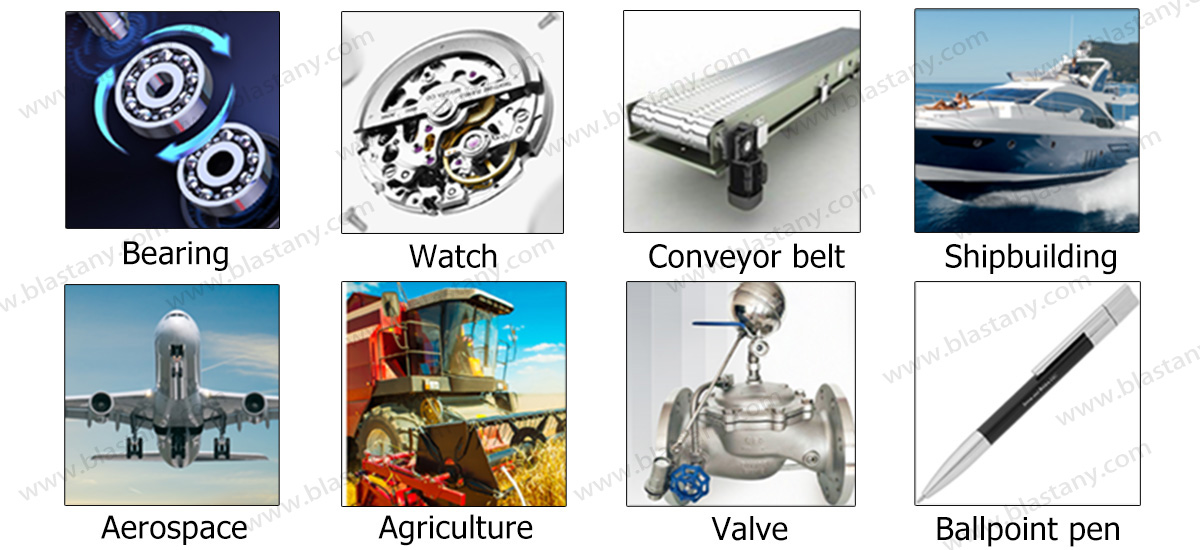

Daim ntaub ntawv: Bearings, stamping, hydraulic qhov chaw, li qub, aerospace, seals, cov khoom siv tub yees, cov cuab yeej siv siab, thiab lwm yam.

| Tshuaj muaj pes tsawg leeg | ||||||||

| AISI 440C | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.95-1.10 Nws | ≤ 0.80 | ≤ 0.80 | ≤ 0.04 | ≤ 0.03 | ≤ 0.60 | 16.0-18.0 Nws | 0.75 ib | |

AISI 420C Stainless hlau pob

Loj: 0.35mm-50.8mm

Qib: G10-G1000

Hardness: HRC50-55

Sib Nqus: Martensitic steel, sib nqus, muaj peev xwm tiv thaiv xeb, siab hardness, AISI 420 stainless hlau pob ua kom pom cov yam ntxwv zoo thiab tawv. Me ntsis hardness thiab ntau dua corrosion kuj, thaum piv rau 440C.

Nta: Feem ntau hu ua stainless hlau, zoo corrosion kuj thiab toughness.

Daim ntaub ntawv: Txhua yam ntawm precision machinery, bearings, khoom siv hluav taws xob, khoom siv hauv tsev, nws pib qhov chaw, thiab lwm yam.

| AISI 420C (4Cr13) | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.36-0.43 Nws | ≤ 0.80 | ≤1.25 | ≤ 0.035 | ≤ 0.03 | ≤ 0.60 | 12.0-14.0 Nws | ≤ 0.60 |

430 stainless hlau pob

Txoj kab uas hla: 1MM-50.80MM

Hardness: HRC26

Qib: G10-G1000

Nta: tus nqi qis, tsis muaj xeb tsis kam.

Daim ntawv thov: kho vajtse, ornaments, accessories, tshuaj pleev ib ce, kev lag luam, industries uas tsis tshua muaj yuav tsum tau rau antirust kev ua tau zoo.Cosmetic agitators, ntsia thawv polish thiab eyeliners, tshav kub exchangers, ntsuas ntsuas. thiab pob valve.

| AISI 430 | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤ 0.12 | ≤1.0 | ≤1.0 | ≤ 0.04 | ≤ 0.03 | - | 16.0-18.0 Nws | - |

AISI 304 Stainless hlau pob

Loj: 0.5mm-63.5mm

Qib: G80-G500

Hardness: ≤HRC21

Sib nqus: Austenitic hlau, tsis-magnetic

Nta: muaj zog xeb kuj, zoo corrosion kuj.widely siv, zoo xeb pov thawj kev ua tau zoo, zoo nto nyhuv, ib puag ncig tiv thaiv ntawv pov thawj.

Daim ntaub ntawv: Cov khoom siv hauv tsev xws li li qub, lub raj mis naj hoom, ntsia thawv polish, menyuam lub raj mis, nws pib qhov chaw, lub tshuab cua txias, cov khoom siv hluav taws xob, tshuaj pleev ib ce, cov kabmob swb, khoom siv kho mob, hniav nyiaj hniav kub thiab ntau lwm yam lag luam.

| Tshuaj muaj pes tsawg leeg | |||||||

| TIAB SA 304 | C | Si | Mn | P | S | Ni | Cr |

| ≤ 0.08 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.03 | 8.0-10.5 Nws | 18.0-22.0 Nws | |

AISI 316L Stainless hlau pob

Loj: 1.0mm-63.5mm

Qib: G80-G500

Hardness: ≤HRC26

Sib nqus: Austenitic hlau, tsis-magnetic

Nta: qhov tsim nyog tshaj plaws rau kev lag luam nrog siab tiv thaiv corrosion, thiab lub peev xwm los tiv thaiv xeb yog muaj zog heev, Zoo heev tiv thaiv corrosion (sib nrug ntawm chloridric acids), Tsis hardenable austenitic inox

Daim ntaub ntawv: AISI 316L stainless hlau pob tuaj yeem siv rau cov khoom siv kho mob, tshuaj lom neeg kev lag luam, aviation, aerospace, yas kho vajtse, naj hoom fwj, tshuaj tsuag, li qub, ntsia thawv polish, lub cev muaj zog, hloov, hlau, tshuab ntxhua khaub ncaws, tub yees, cua txias, khoom siv tshuaj, nws pib qhov chaw, bearings, ntsuas, lub raj mis.

AISI 316L Stainless hlau pob

| Tshuaj muaj pes tsawg leeg | ||||||||

| AISI 316L | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤ 0.08 | ≤ 1.00 | ≤ 2.00 | ≤ 0.045 | ≤ 0.03 | 12.0-15.0 Nws | 16.0-18.0 Nws | 2.0-3.0 Nws | |

Khoom ntim

A) Sab hauv packing: qhuav packingor roj packing yog muab raws li koj xav tau.

B) Sab nraud packing:

1) hlau nruas + ntoo / hlau pallet.

2) 25kg poly hnab + thawv + ntoo pallet lossis ntoo thawv.

customized packing.

Khoom Parameter

| Peb Cov Hlau Stainless Pob muaj xws li 440C 420C 304 316 201, Cov tshuaj muaj pes tsawg leeg yog raws li hauv qab no | |||||||||

| Chemical muaj pes tsawg leeg (%) | C | Cr | Si | Mn | P | S | Mo | Ni | Cu |

| AISI440C SS Pob | 0.95-1.2 Nws | 16-18 | ≤ 0.80 | ≤ 0.80 | ≤ 0.04 | ≤ 0.03 | ≤ 0.75 | ≤0.6 | ---- |

| AISI420C SS Pob | 0.26-0.43 Nws | 12-14 | ≤ 0.80 | ≤1.25 | ≤ 0.035 | ≤ 0.03 | ≤0.6 | ≤0.6 | ---- |

| AISI304 SS Pob | ≤ 0.08 | 18-22 | ≤1.0 | ≤ 2.0 | ≤ 0.045 | ≤ 0.03 | ---- | 8-10 | ---- |

| AISI316L SS Pob | ≤ 0.08 | 16-18 | ≤1.0 | ≤ 2.0 | ≤ 0.045 | ≤ 0.03 | 2.0-3.0 Nws | 12-15 | ---- |

| AISI201 SS Pob | ≤ 0.15 | 16-18 | ≤1.0 | 5.5-7.5 | ≤ 0.045 | ≤ 0.03 | ---- | 0.35-0.55 Nws | 1.82 ib |

| AISI430 SS Pob | ≤ 0.12 | 16-18 | ≤1.0 | ≤1.0 | ≤ 0.04 | ≤ 0.03 | ---- | ---- | ---- |

Tsim Nyog

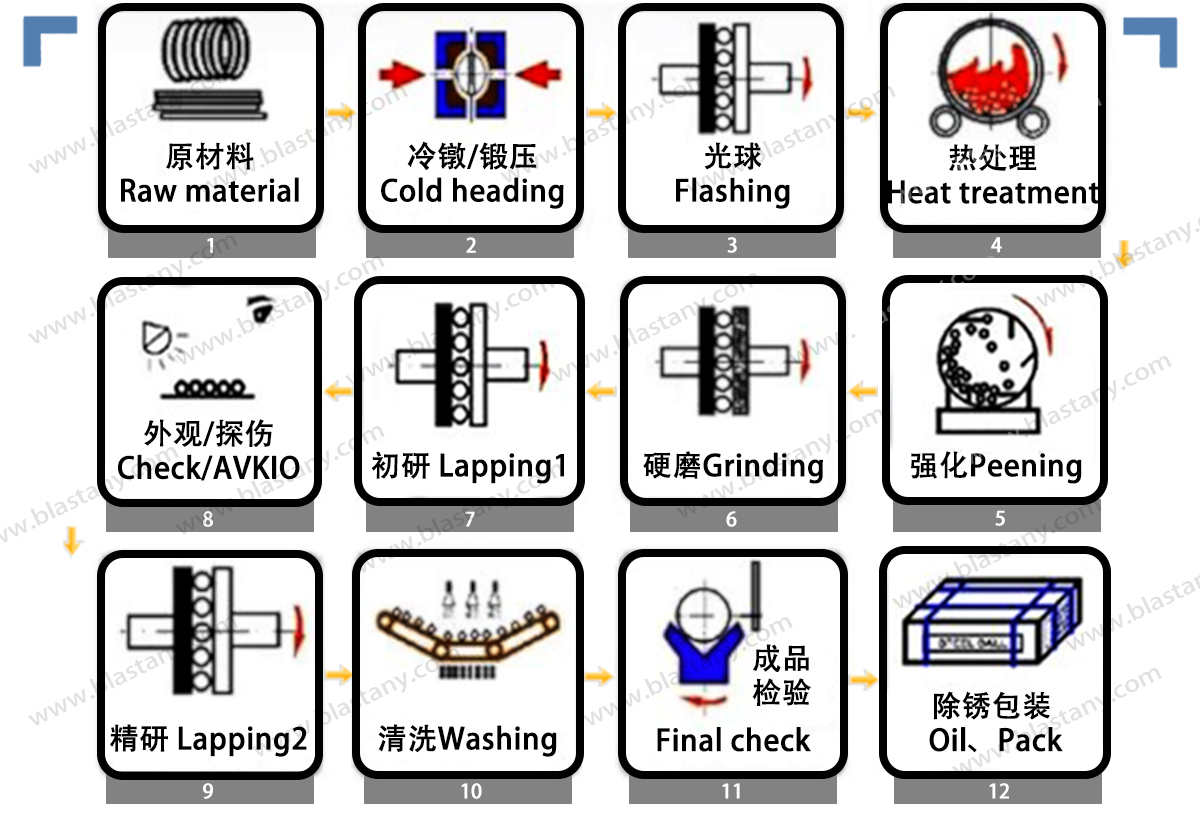

Kev tshuaj xyuas raw khoom

Raw khoom tuaj nyob rau hauv daim ntawv hlau. Ua ntej, cov khoom siv raw yog pom los ntawm cov neeg soj ntsuam zoo los txiav txim siab seb qhov zoo li cas thiab yog tias muaj cov khoom siv tsis raug. Thib ob, txheeb xyuas lub cheeb thiab tshuaj xyuas cov ntaub ntawv pov thawj raw khoom.

Txias taub hau

Lub tshuab txias taub hau txiav ib lub sijhawm ntev ntawm cov khoom siv hlau rau hauv ib lub cylindrical slugs. Tom qab ntawd, ob lub hemispherical halves ntawm lub taub hau tuag tsim cov slug rau hauv ib qho zoo nkauj kheej kheej. Cov txheej txheem forging no yog ua nyob rau hauv chav tsev kub thiab me ntsis ntawm cov khoom siv ntxiv yog siv los xyuas kom meej tias cov kab noj hniav tuag tag. Lub taub hau txias yog ua nyob rau hauv siab heev, nrog rau qhov nruab nrab tshaj tawm ntawm ib lub pob loj ib ob. Cov pob me me yog mus rau ntawm qhov ceev ntawm ob mus rau plaub lub pob ib ob.

Flashing

Thaum lub sijhawm txheej txheem no, cov khoom siv ntau dhau tsim nyob ib puag ncig lub pob yuav raug tshem tawm. Cov pob tau dhau ob peb zaug ntawm ob lub grooved cam khwb cia hlau daim hlau tshem tawm me me ntawm cov khoom siv ntau dhau thaum lawv yob.

Kev kho cua sov

Tom qab ntawd cov khoom yuav tsum tau kho cua sov siv cov txheej txheem quenching thiab tempering.Ib lub qhov cub tawg yog siv los xyuas kom meej tias txhua qhov chaw dais tib yam. Tom qab thawj zaug kev kho cua sov, cov khoom yog immersed nyob rau hauv ib tug roj reservoir. Qhov no ceev ceev txias (roj quenching) tsim martensite, ib theem steel uas yog yus muaj los ntawm siab hardness thiab superior hnav zog. Tom qab tempering ua haujlwm ntxiv txo qis hauv kev ntxhov siab kom txog thaum cov bearings 'qhov kawg kev txwv hardness tau mus txog.

Sib tsoo

Kev sib tsoo yog ua ob qho tib si ua ntej thiab tom qab kev kho cua sov. Finish Grinding (tseem hu ua Hard Grinding) coj lub pob los ze zog rau nws qhov kev xav tau kawg.Qib ntawm precision hlau pobyog ib qho kev ntsuas ntawm nws tag nrho precision; tus lej qis dua, qhov tseeb dua yog pob. Pob qib encompasses txoj kab uas hla kam rau ua, roundness (sphericity) thiab nto roughness kuj hu ua nto tiav. Precision pob manufacturing yog ib qho kev ua haujlwm batch. Ntau qhov loj yog txiav txim siab los ntawm qhov loj ntawm cov tshuab siv rau kev sib tsoo thiab lapping.

Lapping

Lapping zoo ib yam li kev sib tsoo tab sis muaj qhov txo qis ntawm cov khoom tshem tawm. Lapping yog ua tiav siv ob daim hlau phenolic thiab ib qho zoo heev abrasive slurry xws li pob zeb diamond plua plav. Qhov kev tsim khoom kawg no ua kom zoo dua qhov roughness. Lapping yog ua rau lub hom phiaj ntawm high-precision los yog super-precision pob qib.

Ntxuav

Kev ua haujlwm tu tom qab ntawd tshem tawm cov kua dej ua haujlwm thiab cov khoom seem abrasive los ntawm cov txheej txheem tsim khoom. Cov neeg siv khoom uas thov kom muaj kev tu kom nruj dua, xws li cov hauv kev lag luam microelectronics, kev kho mob lossis kev lag luam zaub mov, tuaj yeem siv Hartford Technologies ntau dua kev xaiv tu.

Kev tshuaj xyuas qhov muag

Tom qab thawj txheej txheem tsim khoom, txhua qhov ntau ntawm cov pob steel hlau tau dhau los ua ntau yam kev tswj xyuas zoo. Kev tshuaj xyuas qhov muag yog ua los xyuas qhov tsis xws luag xws li xeb lossis av.

Roller Gauging

Cov menyuam gauging yog 100% cov txheej txheem kev txheeb xyuas uas sib cais ob qho tib si hauv qab-loj thiab dhau-loj precision steel npas. Thov tshawb xyuas peb qhov sib caisvideo ntawm cov txheej txheem kev ntsuas cov menyuam.

Kev Tswj Xyuas Zoo

Txhua lub npas precision raug tshuaj xyuas kom ntseeg tau tias qib yuav tsum tau ua rau txoj kab uas hla kam rau ua, roundness thiab nto roughness. Thaum lub sij hawm tus txheej txheem no, lwm yam tseem ceeb yam ntxwv xws li hardness, thiab tej yam uas yuav tsum tau pom kuj raug soj ntsuam.

Cov khoom qeb