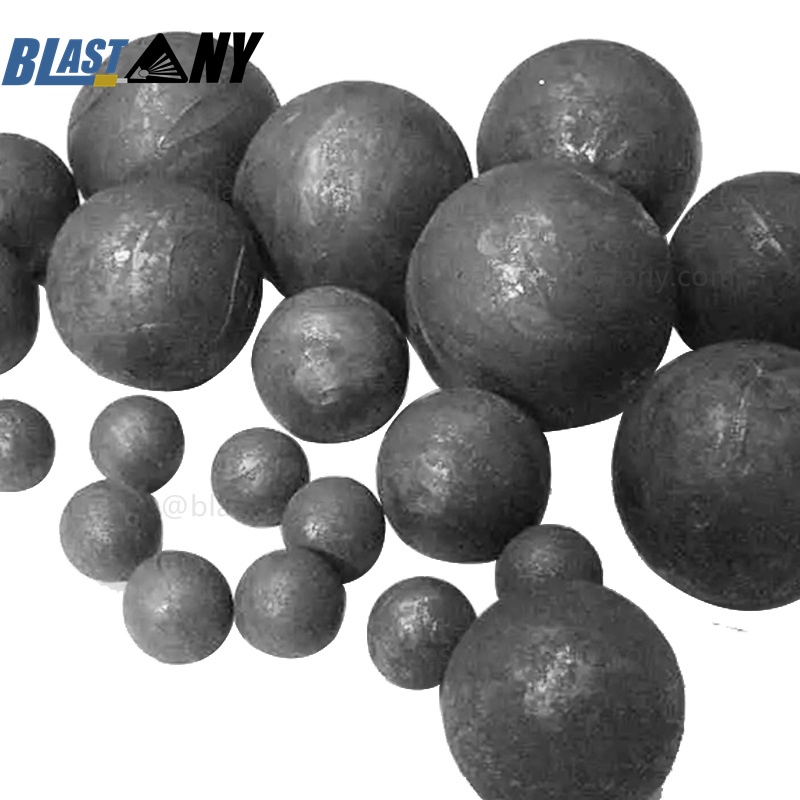

Lag luam wholesale Zoo Zoo Zirconia Sib Tsoo Media Hlaws, Yttrium Stabilized Zirconium Oxide Sib Tsoo Pob

Peb niaj hnub ntseeg tias ib tus cwj pwm txiav txim siab cov khoom zoo, cov ntsiab lus txiav txim siab cov khoom zoo, ua ke nrog REALISTIC, EFFICIENT THIAB INNOVATIVE crew spirit rau Good Wholesale Vendors Zirconia Grinding Media Beads, Yttrium Stabilized Zirconium Oxide Grinding Balls, Koj qhov kev nug yuav zoo siab txais tos peb.

Peb niaj hnub ntseeg hais tias ib tus cwj pwm txiav txim siab cov khoom 'siab zoo, cov ntsiab lus txiav txim siab cov khoom' siab zoo, ua ke nrog REALISTIC, EFFICIENT AND INNOVATIVE crew crew spirit rauTuam Tshoj Sib Tsoo Pob thiab Nano Pob Zeb, Nws yog peb cov neeg siv khoom txaus siab rau peb cov khoom muag thiab cov kev pabcuam uas ib txwm txhawb peb kom ua tau zoo dua hauv kev lag luam no. Peb tsim kom muaj kev sib raug zoo nrog peb cov neeg siv khoom los ntawm kev muab lawv xaiv loj ntawm cov nqi tsheb ntawm cov nqi qis. Peb muab cov nqi lag luam wholesale ntawm tag nrho peb cov khoom zoo yog li koj tau lees tias kev txuag nyiaj ntau dua.

Kev tsim khoom

Tom qab kuaj xyuas thiab ntsuas cov khoom siv hlau puag ncig, cov khoom tuaj yeem pib raws li qhov loj ntawm lub pob steel. Cov hlau forging yog rhuab mus rau ib qho kub los ntawm intermediating nrog zaus rauv los xyuas kom meej qhov zoo tiam ntawm cov variables nyob rau hauv lub forging; Cov hlau liab-kub forging yog xa mus rau hauv cov cua rauj thiab ua tiav los ntawm cov neeg ua haujlwm txawj. Tom qab forging lub pob liab kub steel tam sim ntawd rau hauv JUNDA tshwj xeeb tsim cov khoom siv kho cua sov rau quenching thiab tempering tshav kub kev kho mob, qhov siab thiab zoo hardness tus nqi ntawm lub pob steel tuaj yeem ua kom ntseeg tau.

Feature

1.High impact toughness

2.Compact lub koom haum

3.High hnav tsis kam

4. Tsawg tawg tus nqi

5. Uniform hardness

6. Tsis muaj deformation

Ntim Thiab Thauj Khoom

| Thawv Hnab | Hlau Nruas | |

| Net nyhav 1000kgs rau txhua lub pob loj | Pob loj | Net nyhav |

| 20-30 hli | 930-1000 KGS | |

| 40-60 hli | 900-930 KGS | |

| 70-90 hli | 830-880 KGS | |

| 100mm thiab siab dua | 830-850 KGS | |

| Hnab: 73 × 60cm, 1.5KG, 0.252CBMDrum: 60 × 90cm, 15-20KG, 0.25CBMPallet Ib leeg: 60 × 60 × 9cm, 4-6KG: Ob: 120 × 60 × 10cm, 12-14KG | ||

Lus ceeb toom

1.JD SG4-4 series yog cov khoom siv tshwj xeeb rau JD siab sandblasting tshuab.

2. Kho cov degree ntawm nruj ntawm cov sib koom ua ke nyob rau hauv ib txoj kev kho lub spinning ceev ntawm spinning nozzle yas dhos. Thiab qhov ceev yuav tsum tau tswj tsis pub dhau 30 ~ 500r / min.

3.Yog spinning nozzle tuav nres spinning los yog spinning qeeb heev, nws yuav yog vim nyob rau hauv siab, nruj sab nraud sib koom tes, daig bearings los yog jamed nozzle. Nres lub tshuab, thiab tom qab ntawd kho thiab xyuas.

4. Ua ntej ua haujlwm, cov kav dej hauv phab ntsa sandblaster yuav tsum muab tso rau hauv cov phab ntsa ntawm ib sab mus rau lwm qhov, thiab cov cua txias yuav tsum tau nkag. Thaum ua hauj lwm, blasting yeeb nkab yuav tsum tau rub tawm maj mam kom nws tawm ntawm qhov ceev tsis tu ncua. Yog tias qhov kev tu tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua, ua haujlwm dua kom tau txais txiaj ntsig zoo.

5.Yog tias cov abrasives raug thaiv thiab tsis tuaj yeem txau tawm, nws yuav tsum raug kaw ua ntej thiab tso pa tawm, tom qab ntawd yuav tsum tau kuaj xyuas. 6). Cov khoom siv ceev ceev yuav tsum tau kuaj xyuas tsis tu ncua, lawv yuav tsum tau hloov raws sij hawm yog tias hnav, los yog lawv yuav muaj kev cuam tshuam tsis zoo rau kev ua haujlwm zoo thiab blasting zoo, thiab tej zaum Exhaust coj teeb meem.

Technical parameters

| Technical parameters ntawm forging steel pob | ||||||||||||

| Ntiv | Loj | T luj | Kev kam rau siab (mm) | Khoom siv | Nto hardness (HRC) | Volume hardness (HRC) | ||||||

| 3/4 " | D20 hli | 0.037+/-0.005 | 2+/-1 | B2 | 63-66 : kuv | 63-66 : kuv | ||||||

| 1 ″ | D25 hli | 0.072+/-0.01 | 2+/-1 | B2 | 63-66 : kuv | 63-66 : kuv | ||||||

| 11/4 " | D30 hli | 0.13+/- 0.02 | 2+/-1 | B2 | 63-66 : kuv | 63-66 : kuv | ||||||

| 11/2 " | D 40 mm | 0.30+/- 0.04 Nws | 2+/-1 | B2 | 62-66 : kuv | 62-66 : kuv | ||||||

| 2 ″ | D50 hli | 0.6 +/- 0.05 | 2+/-1 | B2 | 62-65 : kuv | 61-64 : kuv | ||||||

| 21/2 " | D60 hli | 1.0+/- 0.05 | 2+/- 1.5 | B2 | 62-65 : kuv | 60-62 : kuv | ||||||

| 21/2 " | d65mm ua | 1.3 +/- 0.05 | 2+/- 1.5 | B2 | 61-64 : kuv | 60-62 : kuv | ||||||

| 21/2 " | d65mm ua | 1.3 +/- 0.05 | 2+/- 1.5 | B3 | 61-63 : kuv | 60-62 : kuv | ||||||

| 3 ″ | d75mm ua | 2.0+/- 0.06 | 3+/- 2 | B3 | 61-63 : kuv | 60-62 : kuv | ||||||

| 3 ″ (kub dov) | d80mm ua | 2.0+/- 0.06 | 3+/- 2 | B3 | 60-63 : kuv | 60-62 : kuv | ||||||

| 3 "(Forged) | d80mm ua | 2.1 +/- 0.06 | 3+/- 2 | B3 | 60-62 : kuv | 53-57 : kuv | ||||||

| 31/2 " | d90mm ua | 3.0+/- 0.07 | 3+/- 2 | B3 | 60-63 : kuv | 59-62 : kuv | ||||||

| 4 ″ | D100 hli | 4.1+/- 0.15 | 3+/- 2 | B3 | 60-63 : kuv | 59-62 : kuv | ||||||

| 4.5 " | D115 hli | 6.3 +/- 0.15 | 3+/- 2 | B3 | 60-63 : kuv | 57-60 : kuv | ||||||

| 5 ″ | D125 hli | 8.1 +/- 0.3 | 3+/- 2 | B3 | 59-62 : kuv | 55-60 | ||||||

| Tshuaj muaj pes tsawg leeg | C% | Si% | Mn% | Cr% | P% | S% | Ni% | |||||

| B2 | 0.72-1.03 Nws | 0.15-0.35 dr hab | 0.3-1.2 hli | 0.2-0.6 hli | ≤ 0.035 | ≤ 0.035 | i≤0.25 | |||||

| B3 | 0.53-0.88 Nws | 1.2-2.00 Nws | 0.50-1.20 Nws | 0.7-1.20 Nws | ≤ 0.035 | ≤ 0.035 | i≤0.25 | |||||

Peb niaj hnub ntseeg tias ib tus cwj pwm txiav txim siab cov khoom zoo, cov ntsiab lus txiav txim siab cov khoom zoo, ua ke nrog REALISTIC, EFFICIENT THIAB INNOVATIVE crew spirit rau Good Wholesale Vendors Zirconia Grinding Media Beads, Yttrium Stabilized Zirconium Oxide Grinding Balls, Koj qhov kev nug yuav zoo siab txais tos peb.

Peb niaj hnub ntseeg tias ib tus cwj pwm txiav txim siab cov khoom zoo, cov ntsiab lus txiav txim siab cov khoom zoo, ua ke nrog REALISTIC, EFFICIENT THIAB INNOVATIVE crew spirit rau Good Wholesale Vendors Zirconia Grinding Media Beads, Yttrium Stabilized Zirconium Oxide Grinding Balls, Koj qhov kev nug yuav zoo siab txais tos peb.

Cov lag luam wholesale zooTuam Tshoj Sib Tsoo Pob thiab Nano Pob Zeb, Nws yog peb cov neeg siv khoom txaus siab rau peb cov khoom muag thiab cov kev pabcuam uas ib txwm txhawb peb kom ua tau zoo dua hauv kev lag luam no. Peb tsim kom muaj kev sib raug zoo nrog peb cov neeg siv khoom los ntawm kev muab lawv xaiv loj ntawm cov nqi tsheb ntawm cov nqi qis. Peb muab cov nqi lag luam wholesale ntawm tag nrho peb cov khoom zoo yog li koj tau lees tias kev txuag nyiaj ntau dua.

Cov khoom qeb