High quality cam khwb cia hlau tua nrog siab hnav tsis kam

Qhia

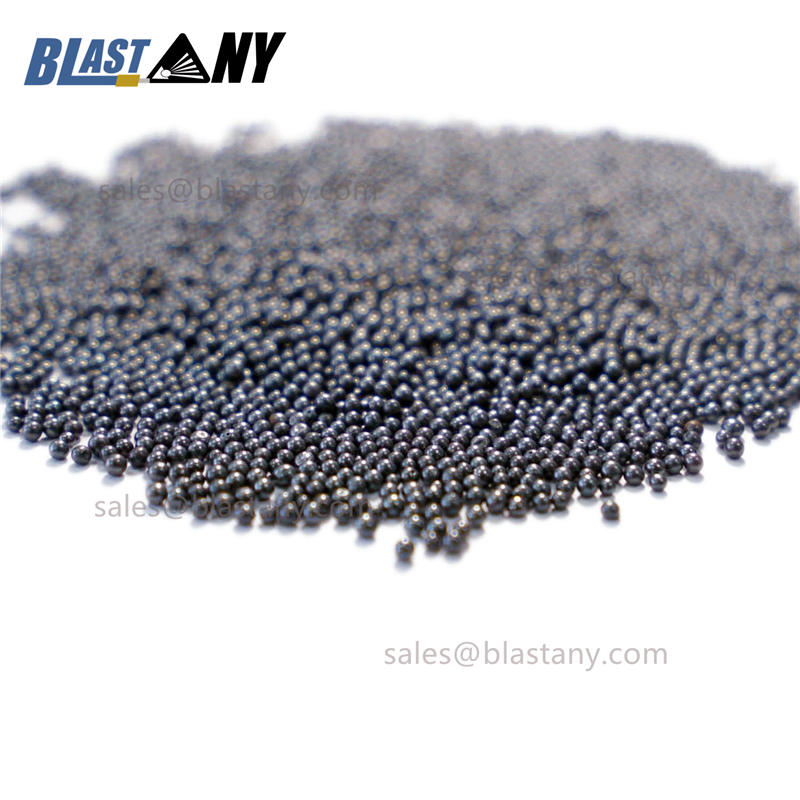

Junda Steel Shot yog tsim los ntawm melting xaiv seem hauv hluav taws xob induction rauv. Cov tshuaj lom neeg muaj pes tsawg leeg ntawm cov hlau molten raug tshuaj xyuas thiab nruj me ntsis tswj los ntawm spectrometer kom tau txais SAE Standard specification. Cov hlau molten yog atomized thiab hloov mus rau hauv ib puag ncig particle thiab tom qab quenched thiab tempered nyob rau hauv cov txheej txheem kho cua sov kom tau ib yam khoom ntawm uniform hardness thiab microstructure, soj ntsuam los ntawm qhov loj raws li SAE Standard specification.

Junda industrial steel txhaj yog muab faib ua plaub, lub teb chaws tus qauv cam khwb cia hlau txhaj tshuaj, muaj chromium cam khwb cia hlau txhaj tshuaj, tshuaj rau cov pa roj carbon tsawg, stainless hlau, nrog rau lub teb chaws tus qauv cam khwb cia hlau txhaj yog kiag li raws li lub teb chaws tus txheej txheem cov ntsiab lus ntawm cov ntsiab lus nyob rau hauv ntau lawm, thiab lub caij ntawm chromium cam khwb cia hlau txhaj tshuaj, yog raws li nyob rau hauv lub teb chaws tus qauv ntawm steel npas, ntxiv ferromanganese ferrochrome nyob rau hauv xws li cov txheej txheem ntev ferrochrome. Tsawg carbon steel tua cov txheej txheem thiab lub teb chaws tus qauv steel tua, tab sis cov khoom siv raw yog cov pa roj carbon tsawg, cov ntsiab lus carbon tsawg dua; Stainless hlau txhaj tshuaj yog tsim los ntawm atomizing txheej txheem, raw khoom yog stainless hlau, 304, 430 stainless hlau thiab lwm yam.

Hom kev txhaj tshuaj no yog tsim los siv rau hauv kev txhaj tshuaj blasting thiab blasting txheej txheem nyob rau hauv siab los ntawm compressed cua. Nws yog siv los ntawm cov hlau tsis muaj hlau xws li txhuas, zinc alloys, stainless hlau, bronze, tooj dag, tooj liab ...

Nrog nws ntau yam ntawm cov qhab nia, nws yog siv rau kev tu, deburring, compaction, txhaj tshuaj peening thiab cov txheej txheem tag nrho, ntawm txhua yam ntawm qhov chaw, tsis muaj paug nws nto los ntawm ferrous plua plav uas deteriorate thiab hloov xim ntawm cov hlau kho. rau cov txheej txheem kev laus ntawm marble thiab granite.

Daim ntawv thov kev lag luam

Hlau txhaj blasting

Hlau txhaj tshuaj ntxuav lub casting xuab zeb thiab burnt -on xuab zeb ntawm lub casting kom nto tau zoo huv si thiab yuav tsum tau roughness, thiaj li yuav tau txais txiaj ntsig rau cov txheej txheem tom ntej thiab txheej.

Cam khwb cia hlau txhaj tshuaj rau Steel phaj nto npaj

Cam khwb cia hlau tua tu cov tawv nqaij oxide, xeb thiab lwm yam impurity los ntawm txhaj tshuaj Blasting, ces siv lub tshuab nqus tsev vacuum los yog purified compressed cua los ntxuav cov khoom steel nto.

Hlau txhaj tshuaj siv rau Engineering machinery

Hlau txhaj tshuaj siv rau Machinery tu tau zoo tshem tawm cov xeb, vuam slag, thiab oxide daim tawv nqaij, tshem tawm cov vuam kev nyuaj siab, thiab ua rau kom yooj yim binding quab yuam ntawm xeb tshem tawm txheej thiab hlau, yog li zoo heev txhim khu lub derust zoo ntawm engineering machinery spare qhov chaw.

Hlau txhaj tshuaj loj rau Stainless hlau phaj tu

Yuav kom ua tiav huv, luminous, exquisite burnish nto kho ntawm stainless hlau phaj, nws yuav tsum xaiv cov ntaub ntawv haum abrasive tshem tawm cov nplai los ntawm txias dov stainless hlau nto.

Raws li cov qib sib txawv, cov hlau tsis xeb hlau yuav tsum xaiv cov kab sib txawv abrasives thiab kev faib ua feem rau txheej txheem. Piv nrog rau cov txheej txheem tshuaj ib txwm muaj, nws tuaj yeem txo tus nqi tu thiab ua tiav cov khoom ntsuab.

Hlau txhaj tshuaj blast media rau Pipeline los tiv thaiv corrosion

Cov yeeb nkab steel xav tau kev kho saum npoo txhawm rau txhawm rau txhim kho corrosion. Los ntawm kev txhaj tshuaj steel, blasting xov xwm polishes, ntxuav thiab tshem tawm cov oxide thiab cov ntawv txuas ua tiav qhov kev thov xeb tshem tawm qib thiab cov nplej qhov tob, tsis tsuas yog ntxuav qhov chaw tab sis kuj txaus siab rau adhesion ntawm cov yeeb nkab steel thiab txheej, ua tiav cov txiaj ntsig zoo los tiv thaiv corrosion.

Steel txhaj peening ntxiv dag zog

Cov hlau qhov chaw ua haujlwm nyob rau hauv cyclic loading mob thiab raug rau qhov kev txiav txim ntawm cycling kev nyuaj siab yuav tsum tau txhaj peening ntxiv zog txheej txheem los txhim kho lub neej qaug zog.

Cam khwb cia hlau txhaj tshuaj Application domains

steel txhaj tshuaj peening yog tsuas yog siv nyob rau hauv kev ntxiv dag zog rau cov khoom tseem ceeb xws li helical caij nplooj ntoos hlav, nplooj hlav, twisted bar, iav, kis tau tus mob qhov chaw, bearing, cam ncej, khoov qag, txuas pas nrig thiab hais txog. Thaum lub dav hlau tsaws, cov iav tsaws yuav tsum tiv taus qhov cuam tshuam loj heev uas nws xav tau kev kho mob peening tsis tu ncua. Cov tis kuj yuav tsum tau kho cov kev ntxhov siab raws sij hawm.

Technical Parameters

| Qhov project | National Standards | Zoo | |

| Tshuaj muaj pes tsawg leeg% | C | 0.85-1.20 Nws | 0.85-1.0 Nws |

| Si | 0.40–1.20 dr hab | 0.70-1.0 Nws | |

| Mn | 0.60-1.20 Nws | 0.75-1.0 Nws | |

| S | <0.05 | <0.030 | |

| P | <0.05 | <0.030 | |

| Hardness | hlau txhaj | HRC40-50 HRC55-62 | HRC44-48 HRC58-62 |

| Qhov ntom | hlau txhaj | ≥7.20g / cm3 | 7.4g 3 |

| Microstructure | Tempered Martensite los yog Troostite | Tempered Martensite Bainite Composite lub koom haum | |

| Qhov tshwm sim | kheej kheej Hollow hais <10% Kev tawg particle <15% | kheej kheej Hollow hais <5% Kev tawg particle <10% | |

| Hom | S70, S110, S170, S230, S280, S330, S390, S460, S550, S660, S780 | ||

| Ntim | Txhua tuj nyob rau hauv ib tug nyias Pallet thiab txhua tuj muab faib nyob rau hauv 25KG pob. | ||

| Durability | 2500 ~ 2800 zaug | ||

| Qhov ntom | 7.4g 3 | ||

| Txoj kab uas hla | 0.2 hli, 0.3 hli, 0.5 hli, 0.6 hli, 0.8 hli, 1.0 hli, 1.2 hli, 1.4 hli, 1.7 hli, 2.0 hli, 2.5 hli | ||

| Daim ntawv thov | 1. Blast tu: Siv rau moj tej tawg tu ntawm casting, tuag-casting, forging; xuab zeb tshem tawm ntawm casting, steel phaj, H hom steel, steel qauv. 2. Kev tshem tawm xeb: xeb tshem tawm ntawm casting, forging, steel phaj, H hom steel, steel qauv. 3. Txhaj peening: Txhaj peening ntawm iav, tshav kub kho qhov chaw. 4. Kev txhaj tshuaj blasting: txhaj tshuaj blasting ntawm profile steel, nkoj board, steel board, steel khoom, steel qauv. 5. Kev kho ua ntej: Kev kho ua ntej ntawm qhov chaw, steel board, profile steel, steel qauv, ua ntej tha xim los yog txheej. | ||

Loj Distribution Ntawm Hlau Txhaj Tshuaj

| SAE J444 Standard Steel txhaj tshuaj | Screen No. | In | Screen loj | |||||||||||

| s930 ua | S780 | S660 | S550 | S460 | S390 | S330 | S280 | S230 | S170 | S110 | S70 | |||

| TXHUA dhau | 6 | 0.132 ib | 3.35 Nws | |||||||||||

| Txhua Pass | 7 | 0.111 ib | 2.8 | |||||||||||

| 90% min | Txhua Pass | 8 | 0.0937 ib | 2.36 ib | ||||||||||

| 97% min | 85% min | Txhua Pass | Txhua Pass | 10 | 0.0787 ib | 2 | ||||||||

| 97% min | 85% min | 5% max | Txhua Pass | 12 | 0.0661 ib | 1.7 | ||||||||

| 97% min | 85% min | 5% max | Txhua Pass | 14 | 0.0555 ib | 1.4 | ||||||||

| 97% min | 85% min | 5% max | Txhua Pass | 16 | 0.0469 ib | 1.18 | ||||||||

| 96% min | 85% min | 5% max | Txhua Pass | 18 | 0.0394 ib | 1 | ||||||||

| 96% min | 85% min | 10% max | Txhua Pass | 20 | 0.0331 ib | 0.85 ib | ||||||||

| 96% min | 85% min | 10% max | 25 | 0.028 ib | 0.71 ib | |||||||||

| 96% min | 85% min | Txhua Pass | 30 | 0.023 ib | 0.6 | |||||||||

| 97% min | 10% max | 35 | 0.0197 ib | 0.5 | ||||||||||

| 85% min | Txhua Pass | 40 | 0.016 5 | 0.425 ib | ||||||||||

| 97% min | 10% max | 45 | 0, 0138 | 0.355 ib | ||||||||||

| 85% min | 50 | 0.011 7 | 0.3 | |||||||||||

| 90% min | 85% min | 80 | 0.007 ib | 0.18 | ||||||||||

| 90% min | 120 | 0.0049 ib | 0.125 Nws | |||||||||||

| 200 | 0.0029 ib | 0.075 ib | ||||||||||||

| 2.8 | 2.5 | 2 | 1.7 | 1.4 | 1.2 | 1 | 0.8 ua | 0.6 | 0.4 | 0.3 | 0.2 | GB | ||

Cov kauj ruam ntau lawm

Cov khoom nyoos

Kev tsim

Qhuav

Kev tshuaj ntsuam

Kev xaiv

Tempering

Kev tshuaj ntsuam

Pob

Cov khoom qeb