Sib tsoo steel pob yog cov xov xwm sib tsoo thiab cov khoom tseem ceeb ntawm lub pob zeb. Lawv tuaj yeem cuam tshuam ncaj qha rau kev sib tsoo ua haujlwm ntawm tag nrho cov ore ua cov nroj tsuag thiab cov khoom lag luam kawg.

Thaum lub sij hawm sib tsoo, sib tsoo steel pob yog siv rau kev sib xyaw thiab milling cov ntaub ntawv (xws li cov ntxhia, xim, thiab tshuaj) rau hauv cov hmoov zoo.

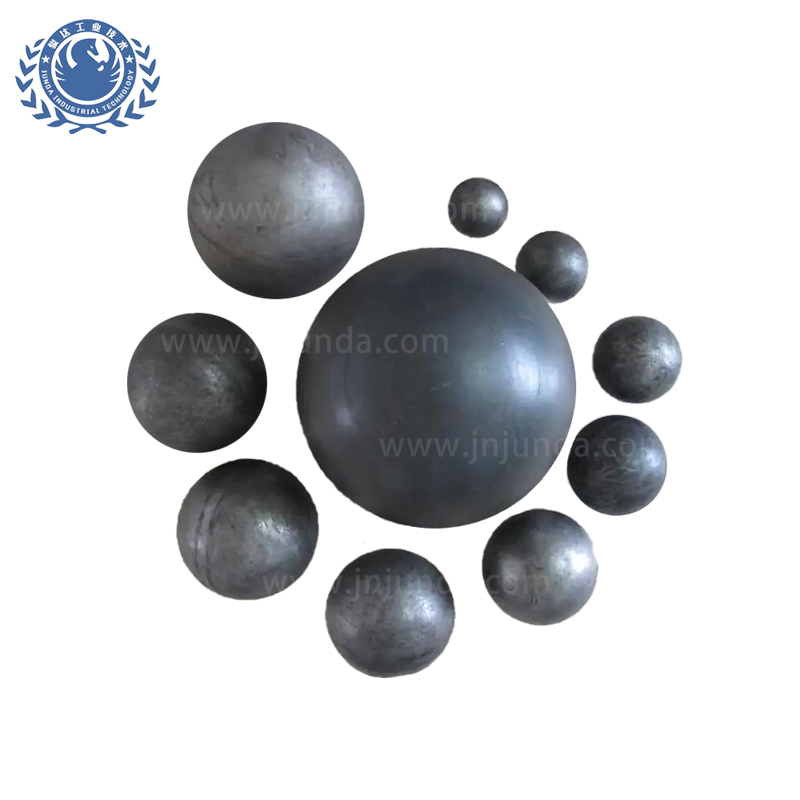

Hom kev sib tsoo steel pob

Raws li kev sib tsoo steel pob xav tau kev puas tsuaj zoo thiab muaj kev cuam tshuam txaus, thiab tsis tuaj yeem tawg, Fote Machinery tau ua qhov kev sim hardness, tshuaj lom neeg muaj pes tsawg leeg tshuaj xyuas thiab tshuaj xyuas sab hauv zoo rau txhua lub pob.

Raws li cov txheej txheem tsim, pob zeb steel pob rau kev tsuas yog muab faib ua forged sib tsoo steel npas thiab cam khwb cia sib tsoo steel pob.

1. Forged sib tsoo steel pob

Xav tau kev sib tsoo ntau dua? Rau kub mining lossis cement kev lag luam? Tom qab ntawd koj tuaj yeem xaiv forged sib tsoo steel pob, uas muaj nyob rau hauv txhua theem ntawm milling.

Fote forged steel pob tuaj yeem muab faib ua cov pa roj carbon tsawg, nruab nrab carbon, siab carbon steel pob raws li qhov feem pua carbon.

Cov ntsiab lus carbon yog qis dua 1.0%. Cov ntsiab lus chromium yog 0.1% -0.5% (feem ntau tsis muaj chromium).

2. Casting sib tsoo steel pob

Raws li lwm hom kev sib tsoo xov xwm, cam khwb cia sib tsoo steel pob tuaj yeem muab Cr (1% -28%), hardness (HRC40-66), thiab txoj kab uas hla (10mm-150mm) alloy cam khwb cia steel pob.

Lawv tuaj yeem muab faib ua cov chromium tsawg, nruab nrab chromium, siab chromium, super siab chromium sib tsoo pob (CR12% -28%).

Fote cam khwb cia sib tsoo steel pob muaj ob lub zog:

Tsawg crushing piv: Qhov tsis kam rau flaking thiab crushing yog 10 npaug tshaj li ntawm lwm cov khoom forged. Tus naj npawb ntawm qhov cuam tshuam ntawm cov pob poob tuaj yeem ncav cuag ntau dua 100,000 zaug. Qhov tseeb crushing tus nqi yog tsawg dua 0.5%, ze rau tsis muaj crushing.

Kev ua kom zoo ntawm qhov chaw: Lub pob saum npoo tsis raug tso cai kom muaj qhov tsis xws luag, xws li cov kab nrib pleb, pom tseeb qhov pores, suav nrog, qhov shrinkage, txias rwb thaiv tsev, ntxhw tawv, thiab lwm yam.

Forged VS Cast sib tsoo steel pob

Ob hom kev sib tsoo steel pob muaj qhov sib txawv hnav, raws li lawv tau ua tiav los ntawm Forged sib tsoo steel pob: Dej quenching feem ntau yog siv rau forging steel pob, yog li nws cov nqi tawg yog siab.

Cam khwb cia sib tsoo steel pob: Nws txais qhov kub-kub quenching thiab tempering kho kom cov sib tsoo pob ntau tawv thiab hnav-resistant.

Yog li, kev sib piv hnav tsis kam yog qhia hauv qab no:

Casting sib tsoo steel pob> forged sib tsoo steel pob. Thiab ntawm cov cam khwb cia hlau pob, siab chromium pob> nruab nrab chromium pob> tsawg chromium pob.

Post lub sij hawm: Jan-17-2024