Cov hlaws iav muaj ntau dua "nto-phooj ywg" piv rau ntau lwm yam abrasives, xws li alumina, silicon carbide, thiab steel grit. Cov yam ntxwv no feem ntau yog ntaus nqi rau nws lub cev thiab tshuaj lom neeg. Lub nto-phooj ywg ntawm iav hlaws yog tshwm sim nyob rau hauv lub peev xwm los ntxuav los yog polish nto zoo thaum txo kev puas tsuaj rau cov khoom ua haujlwm nws tus kheej.

Cov hauv qab no yog ob peb yam tseem ceeb uas ua rau muaj qhov tshwm sim no:

1.Shape and Structure: Spherical vs. Angular

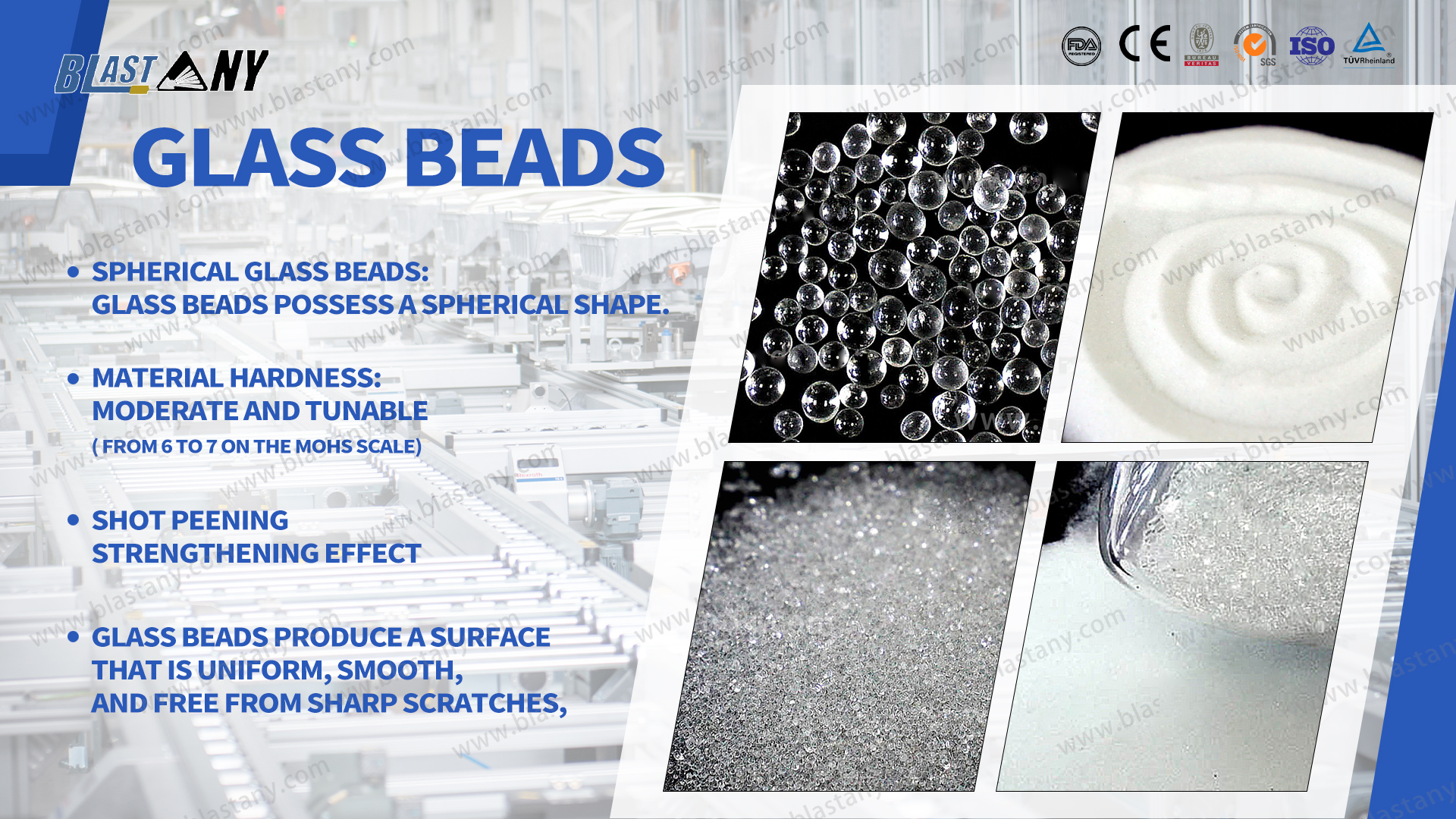

- Spherical Glass Beads: Cov iav hlaws muaj cov duab kheej kheej. Thaum lub sij hawm sandblasting txheej txheem ntawm workpiece nto, lawv tsim cov ntsiab lus hu. Hom kev sib cuag no ua rau muaj kev ntxhov siab tsawg. Qhov kev txiav txim siab zoo ib yam li "tapping" lossis "dov" cov nyhuv, feem ntau yog ua haujlwm kom tshem tawm cov kab mob tsis zoo, xws li cov txheej xeb thiab cov xim qub, tsis muaj kev nkag mus rau hauv cov khoom ua haujlwm.

- Angular Abrasives: Hauv qhov sib piv, abrasives zoo li xim av corundum, steel grit, thiab tooj liab slag feem ntau muaj cov npoo ntse thiab tsis sib xws. Thaum siv rau sandblasting, lawv ua kab lossis taw tes tiv tauj, ua rau muaj kev ntxhov siab hauv zos. Qhov no yog qhov zoo sib xws rau ntau qhov me me chisels carving saum npoo.

Cov duab kheej kheej ntawm cov iav hlaws zoo tiv thaiv kev txiav thiab pitting los ntawm cov npoo ntse, yog li txo qis workpiece hnav thiab txo qhov nce ntawm qhov roughness.

2.Material Hardness: Nruab nrab thiab Tunable

Lub hardness ntawm iav hlaws feem ntau yog li ntawm 6 mus rau 7 ntawm Mohs nplai. Qhov hardness theem no yog txaus los tshem tawm cov kab mob sib kis, xws li xeb (nrog Mohs hardness ntawm 4 - 5) thiab cov xim qub. Ib txhij, nws yog qis dua los yog piv rau hardness ntawm ntau cov ntaub ntawv hlau.

3. Txhaj Peening Strengthening nyhuv

Qhov cuam tshuam ntawm cov iav hlaws rau ntawm cov hlau qhov chaw ua rau muaj qhov sib xws thiab feeb compressive txheej txheej. Cov txheej no muaj ntau yam txiaj ntsig:

- Txhim kho kev qaug zog: Nws txhim kho lub zog qaug zog ntawm cov khoom hlau, zoo tiv thaiv qhov pib thiab nthuav tawm ntawm cov kab nrib pleb.

- Txo Kev Nyuaj Siab Corrosion Risk: Cov txheej txheem kev ntxhov siab yuav txo qis qhov ua rau muaj kev ntxhov siab corrosion.

- Txhim kho hnav tsis kam: Los ntawm kev ua haujlwm txias me ntsis rau ntawm qhov chaw, nws txhim kho qhov hnav tsis kam ntawm cov khoom.

4. Nto tiav

Vim lawv cov duab kheej kheej thiab cov yam ntxwv cuam tshuam, cov hlaws iav tsim ib qhov chaw uas zoo ib yam, du, thiab tsis muaj khawb, feem ntau hu ua "satin finish". Qhov kev ua tiav no muab cov txheej txheem zoo tshaj plaws rau kev txau tom ntej, txheej txheej, lossis electroplating txheej txheem, ua kom muaj zog txheej adhesion.

Conversely, angular abrasives tsim ib tug ntxhib saum npoo topography nrog peaks thiab hav. Txawm hais tias qhov no tuaj yeem txhim kho qhov adhesion rau qee qhov, nws siv cov khoom siv ntau txheej thiab ua rau lub ntsej muag tsis zoo nkauj zoo nkauj.

Raws li cov txiaj ntsig zoo no, cov hlaws iav feem ntau siv rau hauv cov ntawv thov uas qhov kev ncaj ncees ntawm cov substrate yog qhov tseem ceeb tshaj plaws, xws li kev ua cov khoom precision, pwm, cov khoom siv hauv aerospace, cov khoom tsis muaj steel hlau, thiab txhuas alloy tuag-castings. Lawv sawv cev rau qhov kev xaiv zoo tshaj plaws rau kev ua tiav qhov sib npaug ntawm kev tu kom zoo thiab kev tiv thaiv substrate.

Yog xav paub ntxiv, thov koj xav tham nrog peb lub tuam txhab!

Lub sij hawm xa tuaj: Sep-18-2025