Stainless hlau txhaj tshuaj nrog atomization txoj kev siv tshuab

Daim ntawv thov teb

1.Nto xov ntawm aluminium zinc tuag casting thiab nto tu ntawm txhuas xuab zeb casting. Artificial Marble nto txau thiab polishing. Kev tu thiab ua tiav ntawm high alloy steel casting nto oxide nplai, aluminium alloy cav thaiv thiab lwm yam loj tuag casting qhov chaw, marble nto nyhuv kho thiab antiskid kho.

2.Aluminium zinc tuag casting, deg tu ntawm precision casting, nto roughening ua ntej txheej tshwj xeeb, refined tsuag polishing ntawm txhuas profile kom tshem tawm nto extrusion kab, refined spray polishing ntawm tooj liab txhuas yeeb nkab nto, thiab refined spray polishing ntawm stainless hlau thawv thiab valve.

3. Ntxuav cov cuab yeej txias txias, chromium plating tuag rau forging tuag thiab cov log tsheb, kho lub twj tso kua mis ntawm lub tsheb cav supercharger, ntxiv dag zog rau cov iav precision thiab lub caij nplooj ntoos hlav ntawm lub oob khab, thiab tshuaj tsuag polishing nto ntawm stainless hlau thawv.

4.Aluminium zinc tuag casting, maus taus cav lub thawv, lub tog raj kheej taub hau, carburetor, lub cav roj twj tso kua mis plhaub, lub raj xa dej, lub tsheb xauv. Qhov saum npoo ntawm qhov tsis tshua muaj siab tuag casting log profile yuav tsum tau ntxuav thiab ua tiav ua ntej pleev xim. Deg xov thiab tu ntawm tooj liab aluminium stainless hlau stamping qhov chaw, peev casting stainless hlau qhov chaw, thiab lwm yam.

Technical Parameters

| Qhov project | 304 Zoo | 430 Zoo | |

| Tshuaj muaj pes tsawg leeg% | C | 0.08-1.0 Nws | <0.2 |

| Si | 0.4-1.2 hli | <1.5 | |

| Mn | 0.35-1.2 Nws | 0.8-1.2 hli | |

| S | <0.05 | <0.05 | |

| P | <0.05 | <0.05 | |

| Cr | 15-16.5 Nws | 15-17 | |

| Ni | 5-8% | 0 | |

| Hardness | HRC40-50 | HRC35-50 | |

| Qhov ntom | 7.00 g / cm3 | ||

| Microstructure | austenitic | Ferrite | |

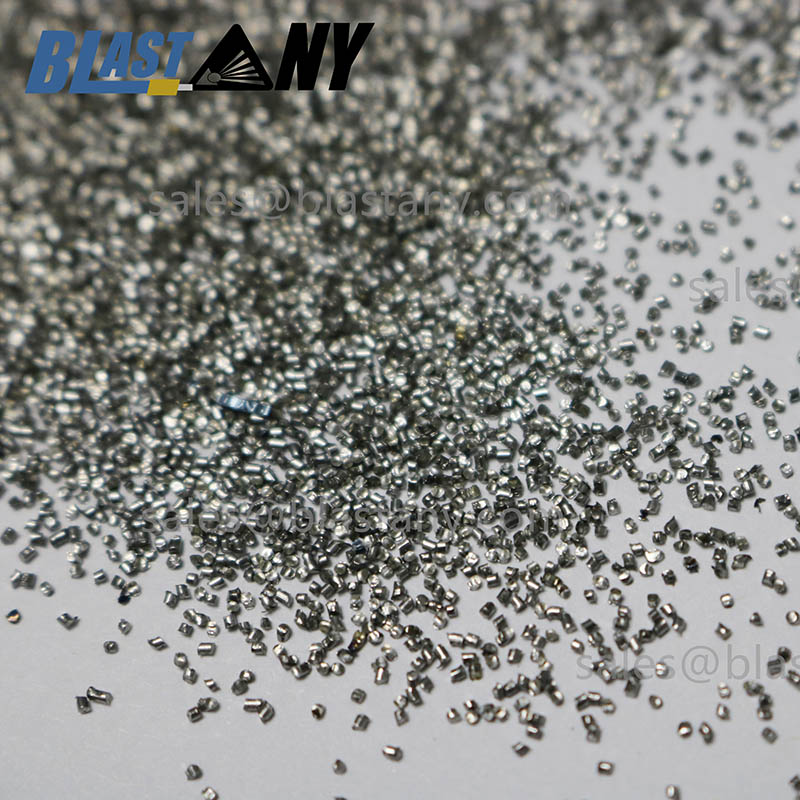

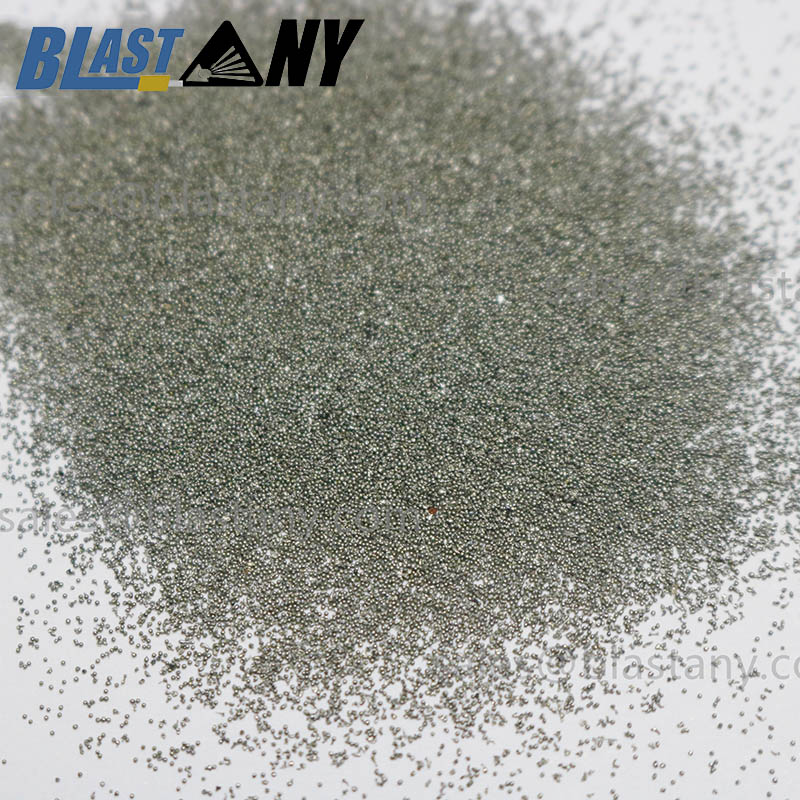

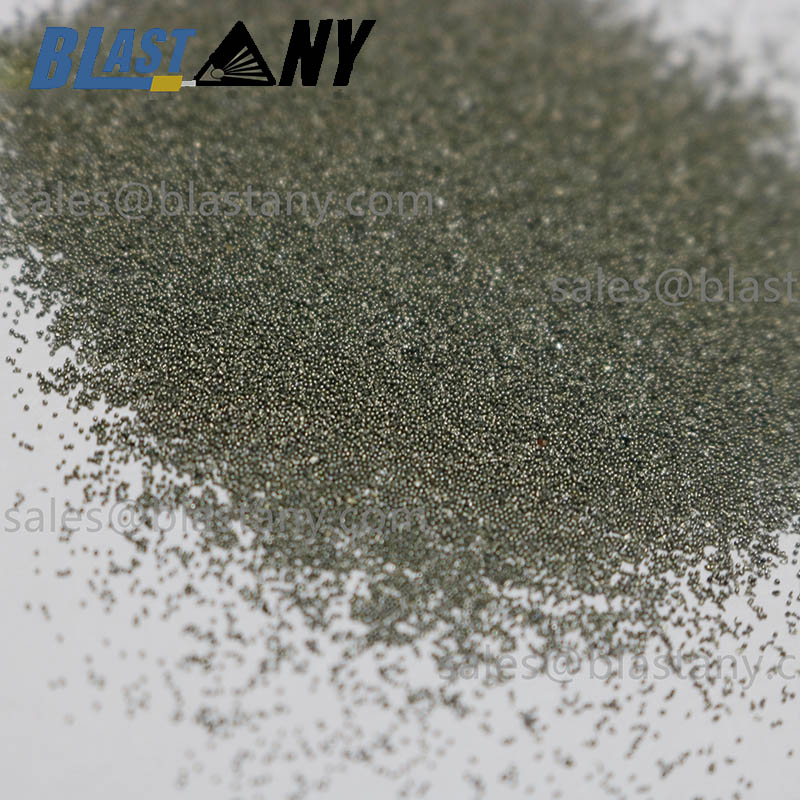

| Qhov tshwm sim | kheej kheej Hollow hais = 0% Hollow hais = 0% | ||

| Hom | 14-18 # / 16-20 # / 20-25 # / 25-30 # / 30-40 # / 40-70 # / 70-140 # / 140-270 # | ||

| Ntim | Txhua tuj nyob rau hauv ib tug nyias Pallet thiab txhua tuj muab faib nyob rau hauv 25KG pob. | ||

| Durability | 27000 ~ 28000 zaug | ||

| Qhov ntom | 7.0g 3 | ||

| Daim ntawv thov | Nws yog tsuas yog siv rau deburring thiab nto xov ntawm txhuas tuag casting, zinc alloy tuag casting thiab magnesium alloy tuag casting; nto xov ntawm precision casting, stainless hlau casting thiab toj roob hauv pes thaiv; iav ua, deg tu thiab ntau yam pretreatment ntawm tuag casting pwm. | ||

Daim ntawv thov

| HOM | Pom zoo Scope ntawm kev siv |

| 14-18 # | Ntxuav cov cuab yeej txias txias, chromium plating tuag rau forging log tsheb, kho lub twj tso kua mis npog ntawm lub tsheb cav supercharger, ntxiv dag zog rau cov iav precision thiab lub caij nplooj ntoos hlav ntawm lub oob khab, thiab tshuaj tsuag polishing nto ntawm stainless hlau thawv. |

| 16-20 # | Aluminium zinc tuag casting, deg tu ntawm precision casting, nto roughening ua ntej txheej tshwj xeeb, refined tsuag polishing ntawm txhuas profile kom tshem tawm nto extrusion kab, refined spray polishing ntawm tooj liab txhuas yeeb nkab nto, thiab refined spray polishing ntawm stainless hlau thawv thiab valve. |

| 20-25 # | Aluminium zinc tuag casting, maus taus cav lub thawv, lub tog raj kheej taub hau, carburetor, lub cav roj twj tso kua mis plhaub, lub raj xa dej, lub tsheb xauv. Qhov saum npoo ntawm qhov tsis tshua muaj siab tuag casting log profile yuav tsum tau ntxuav thiab ua tiav ua ntej pleev xim. Deg xov thiab tu ntawm tooj liab aluminium stainless hlau stamping qhov chaw, peev casting stainless hlau qhov chaw, thiab lwm yam. |

| 25-30 # | Aluminium zinc tuag casting nto xov, aluminium xuab zeb casting nto tu. Qhov saum npoo ntawm cov khoom siv marble yog txau thiab polished. |

| 30-40 # | Ntxiv nrog rau wg40 muaj nuj nqi, qhov saum npoo ntawm stainless hlau casting yog du thiab zoo. Descaling kev kho mob ntawm alloy steel forgings. Artificial marble nto finishing nyhuv thiab antiskid kho. |

| 40-70 # | High alloy steel casting nto oxide daim tawv nqaij, aluminium alloy cav thaiv thiab lwm yam loj tuag casting qhov chaw tu thiab ua tiav, marble nto nyhuv kev kho mob thiab kev kho mob los tiv thaiv. |

| 70-140 # 140-270 # | Qhov saum npoo ntawm cov hlau casting yog deaerated ua ntej txheej, tsheb log hub, cav plhaub kho, granite khoom thiab marble kauj ruam roughening thiab anti-skid kho. |

Granularity

| ScreenNO. | Screensize mm | In | 14-18 | 16-20 | 20-25 | 25-30 | 30-40 | 40-70 : kuv | 70-140 : kuv | 140-270 : kuv |

| 14 | 1.4 | 0.0555 ib |

|

|

|

|

|

|

|

|

| 16 | 1.18 | 0.0469 ib |

|

|

|

|

|

|

|

|

| 18 | 1 | 0.0394 ib |

|

|

|

|

|

|

|

|

| 20 | 0.85 ib | 0.0331 ib |

|

|

|

|

|

|

|

|

| 25 | 0.71 ib | 0.0278 ib |

|

|

|

|

|

|

|

|

| 30 | 0.6 | 0.0234 |

|

|

|

|

|

|

|

|

| 35 | 0.5 | 0.0197 ib |

|

|

|

|

|

|

|

|

| 40 | 0.425 ib | 0.016 5 |

|

|

|

|

|

|

|

|

| 50 | 0.3 | 0.011 7 |

|

|

|

|

|

|

|

|

| 70 | 0.212 ib | 0.008 3 |

|

|

|

|

|

|

|

|

| 100 | 0.15 | 0.0059 ua |

|

|

|

|

|

|

|

|

| 140 | 0.106 ib | 0.0041 ib |

|

|

|

|

|

|

|

|

| 270 | <0.05 Nws | <0.0019 Nws |

|

|

|

|

|

|

|

|

Cov khoom qeb